SUSTAINABILITY

At UNITED CAPS, we are committed to leaving the world better than we found it. The same innovation that goes into making our products drives our work to tackle some of the packaging world’s most pressing challenges.

BENOIT HENCKES. CEO - UNITED CAPS.

We stand for sustainable growth.

We make products Greener and we help to reduce the carbon footprints of our customers.

WE’VE GOT A PLAN

GOALS

Our aim is caps made from 100% renewable or recycled plastic, using 100% green energy, made by a happy secure workforce, operating in a carbon neutral company.

We create caps that enhance the end-user experience of our customer’s brands. And we strive to do so in a way that sustains the planet and the resources that we all depend on as part of a circular economy for plastic. Setting ambitious goals is essential to this — to drive the innovation and collaboration that makes change possible and to be transparent and accountable about our progress.

THOSE GOALS:

1. Reach our science-based emissions reduction targets.

Our plan to become Net Zero by 2050 centers around a 75% emissions reduction target by 2030 compared with our fiscal year 2020 footprint of 156500 tonnes.

2. Transition our entire manufacturing process to 100% renewable electricity by 2026

3. Create products with net zero carbon impact by 2050

OUR APPROACH

Natural resources make our work possible — and we take responsibility for how we source, use, and recycle the materials we rely on to create our products.

Our goal is to one day make all of our products using only responsibly sourced recycled and renewable materials. We aim to build durable, long-lasting products that enable differentiating total packaging solutions.

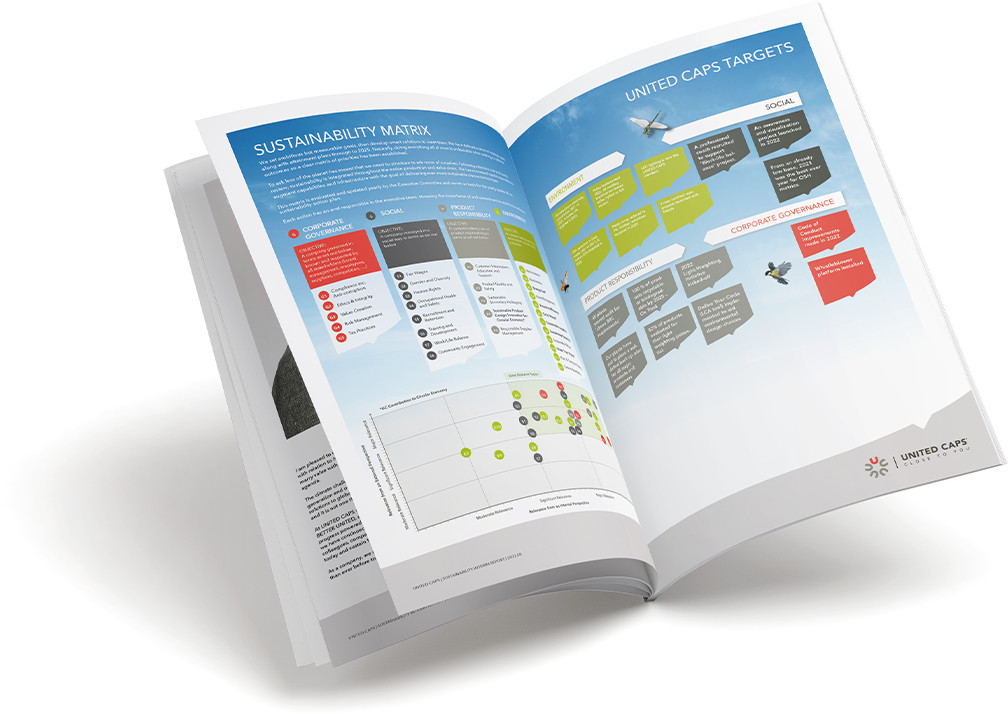

IN THE MATRIX

To ask less of the planet has meant that we need to structure to ask more of ourselves. Following extensive root and branch review, sustainability is integrated throughout the entire production and value chain. We have increased capital expenditure to augment capabilities and infrastructure with the goal of delivering ever more sustainable closure technologies.

This matrix is evaluated and updated yearly by the Executive Committee and serves as basis for the yearly update of our sustainability action plan.

Each action has an end responsible in the executive team, stressing the importance of and commitment to results to be achieved.

MEASUREABLE IMPACT

DEFINE YOUR CIRCLE

Define Your Circle’ is designed to provide UNITED CAPS customers and their customers a simpler way to calculate full life-cycle environmental impact of their products, from before the materials enter the plant right through to its performance in the hands of the end user.

We are constantly looking for actions we can take to reduce the environmental impact of our caps and closures – how they are made, the materials they are constructed from, their weight, how they are sold and how they are distributed. With our industry-first ‘Define Your Circle’ initiative, we have extended that ability to our customers, providing easy-to-use tools that allow us to help them calculate their carbon footprint more accurately, taking actions where appropriate to reduce their life cycle environmental impact and make data-driven informed decisions about their products. We consider this to be a responsible approach to doing business in this era of climate change and negative human impact on the environment.

CARBON FOOTPRINT

This past year we intensified our efforts to reduce UNITED CAPS’ emissions. In 2021, we established measures and processes to gauge and impact our carbon emissions.

The GHG Protocol method is an effective solution for ranking CO2 emissions by source and for launching an active CO2 emissions reduction process.

The GHG Protocol is a worldwide recognized standard developed by a partnership of the World Resources Institute (WRI) and the World Business Council for Sustainable Development (WBCSD).

Every location in the UNITED CAPS family has it’s carbon footprint measured and each has developed a plan to reduce emissions.

Our plan to become carbon neutral by 2050 centers around a 75 percent emissions reduction target, compared with our fiscal year 2020 footprint of 156500 tonnes.

We plan to address residual emissions through carbon offsetting.

IN THE PLANT

Good intentions are important but at UNITED CAPS they manifest into action that impacts our product portfolio, how they are made, the materials they are constructed from, how they are sold and how they are distributed.

Our production facilities and plants continuously seek to reduce our energy consumption.

We

utilise modern electrical injection moulding machines in all plants in order to significantly

decrease electrical consumption and the usage of cooling water.

Since 2015 UNITED CAPS has grown it’s production facilities by 35% as well as investing in state-of-the-art research facilities in Messia. New production plants in England, France and Malaysia have been developed with process heat recuperation for heating buildings and with LED lighting as standard and are designed to maximise energy efficiency.

Whistleblower

platform installed

IN THE HAND

In an efficient food system, packaging helps make safe, high-quality products accessible to all, extending shelf life and helping to limit food waste. But, for it to have a role in a more sustainable food system, we must eliminate packaging waste.

We are working to fundamentally change the way consumers interact with our portfolio to deliver our vision of a world where plastics need never become waste.

The European Union directive on Single Use Plastic will present new challenges for the entire Industry and an Industry Problem requires an Industry Solution.

Whilst others adopted a more negative, disruptive approach to the proposed Directive, UNITED CAPS worked with like-minded organisations from throughout the supply chain to form the ACT (Association for Closure Tethering) Group.

We engaged in the circularity program ‘CE connect’ of the Belgian Technological Industry Federation and are taking actions on 3 levels in the circular economy for plastic packaging.

- All designs are being screened with LCA on their impact on environment and circularity

- Recycled resin is actively promoted

- Bio-based resin is actively promoted in order to make the switch from fossil based to renewable.

- Stopping leakage from the circular model by participating in the Ocean Clean Sweep Program and recycling all production rejects and secondary packaging materials.

Follow us for social updates